Explain Like I'm 5: Cut-Resistant Gloves

You may have seen online cut-resistant gloves using certain terminology:

- cut level 5

- ANSI A4

- highest cut level

- EN388 cut rated

But what exactly makes a glove cut-resistant? Moreover, how can someone label their gloves as cut-resistant?

The stronger the fabric, the higher the cut level.

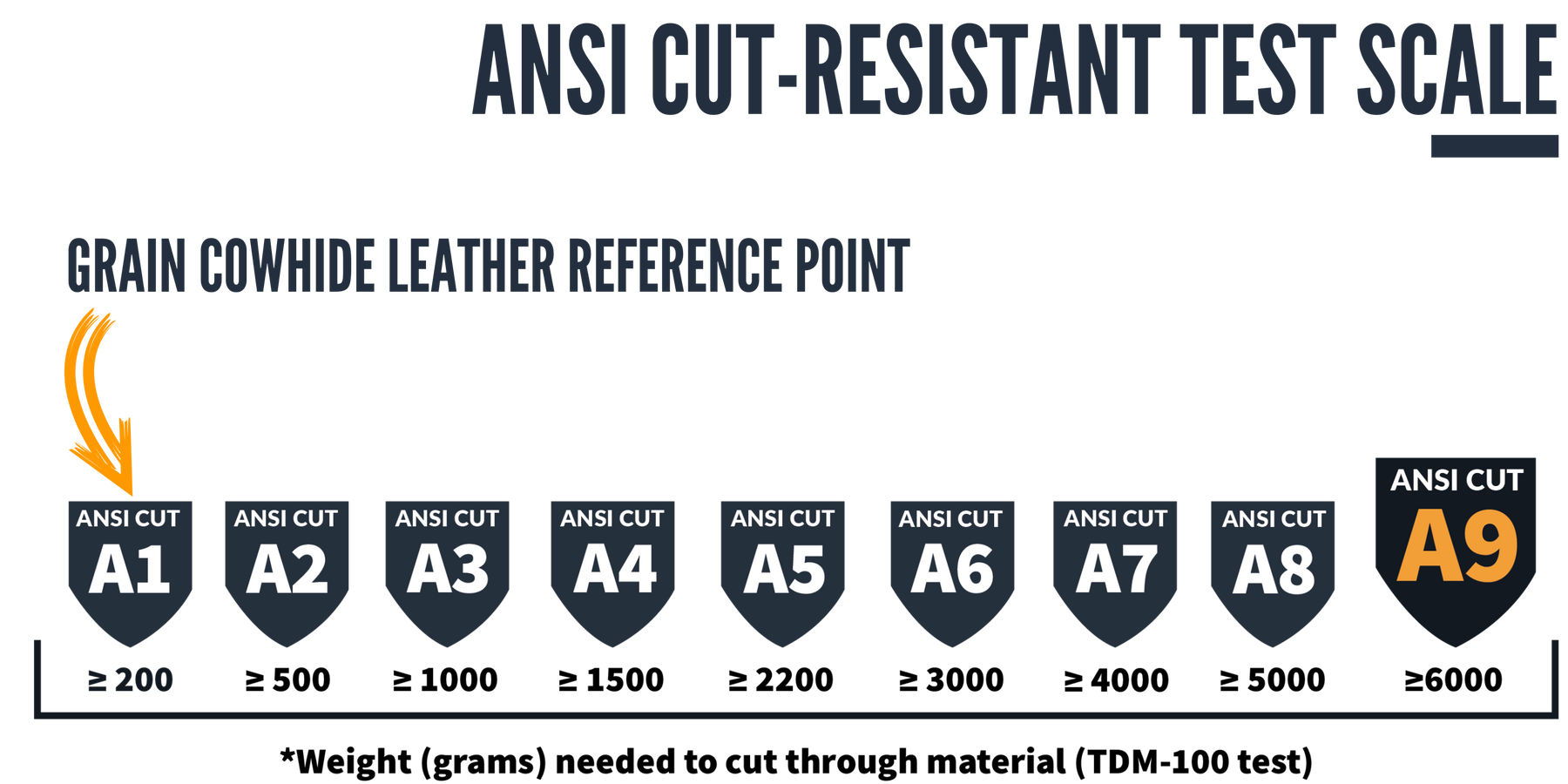

The United States standard for cut-resistance is set by ANSI, the American National Standards Institute.

A machine called a TDM-100 uses a blade to slide across a sample of glove material at different weights and distances. This is conducted multiple times with fresh glove samples to gather the average cutting load using a 20 millimeter reference.

ANSI cut levels are spread into 9 levels, each with increasingly higher cut load.

Now, does an ANSI cut A9 glove have 9x the durability of an A1 glove?

No. The durability may be slightly better since the fabric is stronger, but the main purpose of a high cut glove is the level of intensity load it can handle.

For gloves that claim cut-resistance using EN388, they will leave out "A" in front of the number. This is the European test standard and uses a different test method that is not as effective as ANSI's TDM-100 method. This caused some fabrics to give a higher cut rating than it should have received due to blade blunting. Only in the last couple of years did they implement their own TDM-100 test method.

For most general operations, an ANSI cut A1 would cover most jobs. Think general handling and sorting. Something that would protect you from minor papercuts and abrasion injuries, while providing you with the highest amount of dexterity for precision handling.

At Cestus®, our knit gloves are spun and woven with performance grade fabric, infused with anti-bacterial properties for a fresh and long-lasting wear.

Take a look at our most popular knit, an ANSI cut A1 glove used by many in construction, warehouse, roofing, carpentry, and field operations. Click the image below to check it out or click here.